Electrical providers rely heavily on towers to provide safe and reliable service to regional customers. After all, towers are critical infrastructure and an essential part of electrical operations. But at the same time, towers are prone to mechanical issues and failure.

As such, they need to be periodically inspected to ensure safety, stability, and efficiency. This is particularly important for providers that have towers in remote areas. And it’s also important for providers in locations that are subject to extreme weather conditions. No matter the situation, failure to monitor towers can result in prolonged and expensive outages. And it can also result in safety hazards, bad press, and irate customers.

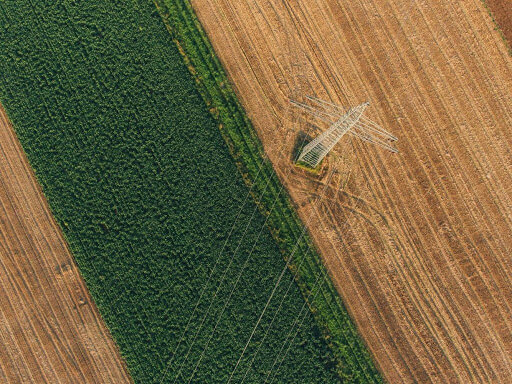

Let’s explore some of the top challenges that electrical providers face when inspecting towers and how they’re using unmanned aerial vehicles (UAVs)—or drones—to streamline monitoring and surveillance.

Top Challenges of Manual Tower Inspections

Tower inspections are still largely conducted manually, using visual sensors. Unfortunately, this is a process that is highly inefficient for many electrical providers. With that in mind, here are some of the top challenges associated with manual tower inspections.

Tower inspections are still largely conducted manually using visual sensors…a process that is highly inefficient for many electrical providers

1. Logistical Issues

Manual inspections create a variety of logistical problems for providers. For starters, they require rolling out trucks and crews and having them assess multiple towers during each shift. This process can be time-consuming and challenging—especially when inspecting towers in remote locations that are not accessible by roads or paths and require either cumbersome helicopters or all-terrain vehicles (ATVs).

Rollouts are also very expensive. This is because they consume heavy amounts of fuel and create wear and tear. Excessive inspections can drive up operating costs while reducing vehicle lifespans, much to the chagrin of operators.

2. Human Resource Issues

Another downside to sending out physical crews into the field to conduct manual inspections is that it’s risky for those conducting the inspections. This issue compounds when dealing with live power lines or dangerous weather conditions, like wind, ice, or rain. In these scenarios, workers are liable to have accidents. In an extreme case, this could lead to significant injuries—and even death.

Further, deploying engineers and specialists takes them away from other tasks and responsibilities. In an age where customer experience is a key differentiator, this is problematic for utility providers that are understaffed and short on resources.

3. Productivity Issues

Depending on the scope of the project, manual tower inspections can take hours or even days to complete. The process is highly inefficient, especially when towers go down for long periods at a time. Electrical providers need to work quickly to identify tower problems and make timely repairs. Failure to do so can result in customer complaints, negative reviews, and penalties, among other bad outcomes.

Streamlining Tower Inspections With Drones

Luckily, companies don’t have to inspect towers the old-fashioned way. In fact, recent advancements in drone technology make it much easier for electrical companies to monitor and repair towers. Companies across all sectors now use drones to augment field inspection teams. This enables technicians to drastically improve the way they track and analyze remote infrastructure.

How Are Electrical Companies Using Drones?

A growing number of electrical providers are now using drones to inspect towers, lines, and power generators. Lightweight, flexible, and cost-effective drones enable crews to conveniently analyze electrical systems over a broad radius. Drones can efficiently move between nearby towers, limiting team movement.

This is an incredible development in a field that’s traditionally been resistant to change.

The Benefits of Using Drones for Tower Inspections

Here are some of the top ways electrical companies benefit from using drones.

Timelier Inspections

Electrical providers often need to move quickly following a major storm, inspecting lines for damages and making critical repairs to restore power. However, this is often very difficult— particularly when crews can’t access towers due to downed trees, flooded rivers, or heavy snowfall.

Here’s an easy fix: It’s much faster and easier to deploy drones, leading to timely inspections and rapid repairs.

Higher-Quality Inspections

Ground and helicopter crews often struggle to perform inspections because it can be difficult to get close to towers and assess them for damages.

On the other hand, drones are much smaller and more agile and therefore more capable of getting closer to critical infrastructure. As such, they are able to take pictures and analyze their components using sensors.

Fewer Accidents

By using drones, inspection crews can analyze towers and lines from the safety of a centralized base station. This is much safer than trudging through harsh environmental conditions and being exposed to the elements.

As an added bonus, drones can give maintenance crews better insight into what they’re dealing with before they’re deployed. For example, a crew could potentially send a drone to inspect an area for downed lines, live wires, and fire hazards ahead of time. By doing so, the team can be better prepared before going in to conduct maintenance. In turn, these advance insights can reduce accidents and save lives.

VLOS vs. BVLOS drones

Drones have come a long way since they were first cleared for commercial aviation by the Federal Aviation Administration (FAA) back in 2014. However, most drones today still have a critical shortcoming: they are only capable of visual line of sight (VLOS) operation. In other words, operators need to have clear visibility and keep drones in sight per federal law, unless they have special permissions.

Because most drones operate as VLOS deployments, crews are still somewhat limited when deploying and using them. Oftentimes, crews need to change locations throughout the day and follow drones into specific areas to set up base stations and conduct aerial surveillance.

- Good news: recent advancements in beyond visual line of sight (BVLOS) operations offer exciting potential for commercial drone usage in the electrical industry. In a BVLOS drone environment, teams do not have to maintain a clear line of sight with their drones. Drones can be deployed from a single location—remotely controlled.

Add it all up, and BVLOS reduces human intervention, enabling drones to go much farther. Using BVLOS, a drone can travel without the threat of interference from trees, mountains, or buildings.

Iris Automation offers Casia, a groundbreaking 360-degree radial computer vision detect-and-avoid system for drones

How Iris Automation Can Help Electrical Companies

Iris Automation offers Casia, a groundbreaking 360-degree radial computer vision detect-and-avoid system for drones. Casia enables electrical providers to safely deploy BVLOS operations, allowing for flexible and efficient tower inspections. In short, Casia offers a safer, faster, and more intelligent approach to drone usage.

With the help of Casia, electrical engineers can deploy drone fleets and monitor critical infrastructure over hundreds of miles, while minimizing truck rollouts and workers. Casia utilizes industrial cameras for highly advanced situational awareness, with real-time data processing and proprietary algorithms to make snap decisions and avoid collisions.

Obtaining a BVLOS Waiver

In most countries, BVLOS operations typically require special approvals from governing agencies. You can’t just deploy a BVLOS operation without gaining permission. Otherwise, you’ll risk facing fines and penalties. Iris Automation offers an abundance of resources to help operators begin their journey with BVLOS drones. For more information, check out the Regulatory Resource Center to learn more about how to obtain approval.

Taking Your Drone Usage to the Next Level

We’re on the cusp of an exciting new era in the utility sector. Technologies like drones are revolutionizing the way that companies manage their infrastructure. Looking ahead, the possibilities are endless—particularly as more and more drones enter the mix.

To learn how Iris Automation can optimize the way your company uses drones, contact the team today.

This post was written by Justin Reynolds. Justin is a freelance writer who enjoys telling stories about how technology, science, and creativity can help workers be more productive. In his spare time, he likes seeing or playing live music, hiking, and traveling.